How To Install Reverse Osmosis Membrane

Contrary Osmosis Installation Diagram

Download Reverse Osmosis Installation Manual Reverse Osmosis Installation Animation

Requires Adobe Acrobat Reader

Likewise view our Exploded Diagrams at the bottom of this guide.

Your Contrary Osmosis (RO) System has been tested to ensure information technology will operate correctly. The post-obit periodic maintenance is recommended so your arrangement will provide years of problem-costless service:

- Pre-filters (Sediment) - Once per twelvemonth

- Pre-filter (Carbon Block(s)) - One time per yr

- RO Membrane - Usually Every 2 years

- Post filter (Carbon) - One time per year

Reverse Osmosis System Components

-

RO Module

The RO module is the main component and holds the pre-filters, membrane, and post-filter. A bracket is provided so they can exist mounted under the sink or in a basement. -

Angle Stop Valve

The angle stop valve connects to the common cold water line to supply water to the RO system and provides an easy power to shut off the h2o supply when servicing the unit of measurement. -

Pre-Filter #1

Melt Blown Polypropylene filter removes larger particles such as dirt, rust & sediment. -

Pre-Filter #2 (And 3 If Applicable)

x Micron Carbon Block removes chlorine and chemical contaminants in the feed h2o and protects the RO membrane. -

Automatic Close-Off Valve

Automatic shut-off valve closes when the storage tank is full and shuts off the h2o supply to conserve water. The valve activates when the tank pressure is two/three of the feed pressure. -

Membrane

Reverse Osmosis Membrane Sparse Motion-picture show Composite Membranes reduces dissolved minerals, metals, and salts. In this process, harmful compounds are separated by the membrane from the water, and the contaminants are flushed to the drain. -

Post-Filter

A coconut shell activated carbon post filter is provided for a final "polish" and to remove tastes, odors and to provide great tasting h2o. -

Bladder Tank

Bladder tank holds RO purified h2o, ready to use. -

Drinking Water Faucet

The RO Faucet is used to dispense purified water when yous desire information technology. -

Bleed Clamp

A wastewater saddle valve connects to the drain to remove reject water from the RO system. -

Tubing

Tubing connects all RO components. -

Quick-Connect Fittings

Quick-Connect fittings are used for necessary tubing connections. These fittings connect by pushing the tube into the fitting past a slight resistance until the tube bottoms out in the fitting. Simply make a clean cut in your tubing and gently push in the tubing until it will not get whatsoever farther. To ensure that your tubing has fabricated a snug fit, pull back gently on the tubing; it should catch. E'er check for leaks to ensure a watertight connection. (see Figure 1).

Tools

The following tools may be necessary, depending on each particular installation:

- 3/8" variable speed electric drill; (2,500 RPM is best for stainless steel)

- i/viii", 1/4" & 1/2" metal cutting drill bits

- 1/8", 1/4" & ane/2" concrete drill $.25 (for porcelain sinks)

- Phillips head spiral commuter

- 6" adjustable wrench

- Teflon tape & Plastic tubing cutter

- Hammer & Middle punch

Organization location

Your RO system may be installed under a sink or in a basement. Exercise non install unit where it would be exposed to freezing temperatures. Connecting to an icemaker or other remote location can also be considered if a connection can exist made without using more than 12" of tubing, otherwise a commitment pump may be needed. Farther runs tin be attempted and a pump can be added later on only if needed.

Guidelines for component placement are as follows:

-

Faucet

should be placed on, or near the sink where drinking/cooking water is commonly required. A ii" flat surface is required to mount faucet if an existing hole is not available. The thickness of the mounting surface should not exceed 1-1/4" or a faucet extension (not supplied) will be needed. -

Bladder Tank

maybe placed where it is convenient, within 10 feet of the faucet. Under the sink or in a nearby cabinet or in basement rafters are first-class choices. Full tanks tin weigh more than thirty pounds; so make sure any shelving used is secure. Bladder tank can be placed on its side or upright. -

RO Unit

may exist mounted on either side of the sink, in the back of a chiffonier, or in the basement. Mounting the unit of measurement on the left or the correct side of the cabinet nether the sink provides for easier access to the unit for future maintenance. -

Angle Stop Valve

is used to supply a feed water connection to the RO unit. Locate this assembly every bit close to the RO unit as possible. Connects between the acme of your common cold water shut-off valve and the bottom of the riser tube that runs betwixt your common cold water shut-off and the faucet. Ask your local dealer which alternatives can be used in place of the bending cease adaptor if ane cannot be installed nether your sink. -

A Drain Saddle

is used to make a waste material water connection with your drain nether the sink. This is designed to fit effectually a standard 1-one/2" OD drainpipe. The drain saddle valve should always exist installed before (above) the p-trap and on the vertical or horizontal tailpiece. Do not install the bleed saddle near a garbage disposal to avoid clogging the drain line with debris.

System Grooming

Open aircraft carton, remove components and bank check that all parts are present.

Installation Steps

All plumbing must exist completed in accordance with state and local plumbing codes. Some municipalities may require installation past a licensed plumber. Cheque your local plumbing codes for more than information.

-

one. Faucet Installation

If the sink has a sprayer, it may be disconnected for faucet installation. A pipe cap or plug volition exist necessary to seal the sprayer connexion or sprayer can be left connected under the sink.

To make the faucet-mounting hole (if sprayer hole or other existing hole is non used), check below to make sure the drill will not interfere with anything below. A 2" apartment surface is required, not exceeding i-1/four" thickness.

The faucet should be positioned so it empties into the sink and the spout swivels freely for convenience. If the sink has a hole that can accommodate the RO faucet, no drilling is required. Proceed with mounting the faucet.

Installation procedures for Porcelain, Enamel, Ceramic on Metallic, or Cast Iron:

Precautions must be taken to penetrate the porcelain through to the metal base and prevent chipping or scratching.

Procedures:

- Mark the eye with center punch for the 1/iv" pilot hole.

- Carefully drill pilot hole with masonry pit through porcelain and stop when metal shows. (Use light force per unit area and slow speed)

- Switch the bit to a standard metallic cutting chip to continue to cut through the metal beneath the porcelain surface.

- Continue to enlarge the pilot pigsty with larger masonry & metallic cutting bits until the hole is 1/2".

Installation procedures for stainless steel sinks

Procedures:

- Mark the center with center punch for the 1/4" pilot hole.

- Drill the pilot hole.

- Continue to enlarge hole with larger size drill bit until it is ane/two".

- Clean up abrupt edges.

Note: Air Gap Faucets are required by some municipalities. These faucets crave a i-ane/4" hole in the sink rather than the 1/ii" hole required past the standard faucet included with the RO organization. To brand a 1 ane/4" hole to accommodate an air gap faucet requires special tools such as a chassis punch (stainless steel) or a Relton cutter (porcelain) if a large plenty hole is not already available. Inquire your local dealer for more information.

-

two. Mounting the Faucet

Disassemble hardware from the treaded shank. Chrome base of operations plates and rubber washers slide up the shank to the faucet trunk.

Feed threaded shank through the sink hole and orient the faucet. From below sink, slide lock washer and hex nut over threaded shank and tighten with a wrench.

Annotation: It is all-time to have someone hold the faucet from in a higher place the sink to keep it from moving out of identify. If this is not possible so tighten the hex nut until it is just slightly less than completely tight. Then turn the faucet base of operations from higher up the sink, tightening it while orienting the faucet in the desired location.

-

3. Bending Stop Valve and Tubing Installation

The John Guest Angle Stop Valve provides a elementary, easy connexion betwixt the angle stop (cold water shut-off) and the bottom of the riser tube. The Angle Stop Valve has built-in shut-off and provides the feed supply connectedness for the contrary osmosis arrangement.

Installation procedure: (See Figure 2)

- Shut-off the common cold water supply using the angle stop shut-off located under your sink.

- Subsequently shutting off the valve, salve the pressure by opening the handle on your faucet on the cold water side.

- Using an adjustable wrench, disconnect the riser tube from the existing cold water shut-off.

- Move the tubing away from the valve to brand room for the John Guest Bending Terminate Valve.

- Connect the swivel terminate of the John Guest Bending Terminate Valve to the threads on the cold water shut-off. This connectedness should only exist hand tight.

- Connect the riser tube to the male cease of the John Guest Angle Stop Valve and tighten with a wrench.

- Connect a length of 1/4" tubing between the John Guest Plumbing fixtures on the Angle Stop Valve and the inlet of the RO unit.

Flexible Riser Tubes:

Most riser tubes that are used today are made of flexible material, either braided stainless steel, braided plastic or greyness 3/viii" plastic tubing. These flexible tubes are the easiest to use with the John Guest Angle Finish Valve because the two" of additional space needed for the Faucet Adaptor can exist easily accommodated by flexing this kind of riser. A shorter riser tube will non exist needed.

Copper Riser Tubes:

If your riser tube is made of copper y'all will need to either make a bend in the copper to permit for the two" of space needed for the John Guest Angle Stop Valve. If the copper tube is 3/viii", angle it can be done easily by hand.

The John Guest Angle Cease Valve works with 3/8" shut-off valves and riser tubes. In some cases, older plumbing may use a larger size shut-off and riser tube. In this example, it would be necessary to either replace the old valve and riser tube with new three/viii" parts, or utilise an alternative connection to draw the water supply to the reverse osmosis arrangement. Alternatives include cocky piercing valves, T fittings, and faucet adaptors that connect between the faucet and the top of the riser tube.

Please consult your distributor or an installation professional person for boosted help.

-

four. Drain Saddle Valve Installation

A Drain Saddle is used to brand a wastewater connection with the drain under the sink, which is designed to fit around a standard 1-1/two" OD drainpipe. The drain saddle valve should always be installed before (in a higher place) the p-trap and on a vertical or horizontal drain. Do not install the drain saddle most a garbage disposal to avoid clogging the drain line with droppings.

Installation procedure: (See Figure three)

- Position the drain saddle valve at selected location and mark for the opening.

- Drill 1/4" pigsty at mark through one side of pipe.

- Remove backing from gasket and place adhesive side to the plumbing fixtures half of drain clamp around hole.

- Position both halves of bleed saddle on drain pipe so the opening aligns with drilled hole. Employ a small drill fleck to verify that drain clamp is properly aligned.

- Secure bleed saddle clamp on valve with bolts and nuts provided. (Practice not over tighten and make sure there is equal space betwixt saddle halves on each side)

-

5. Initial Tubing Connections

For convenience on under sink installations it may be advisable to complete nether sink tubing connections at this time.

-

6. RO Component Installation

Cartridge Installation Required

The sediment cartridge, carbon block cartridge(s), and reverse osmosis membrane must all be installed in the RO unit. The cartridges are provided in sanitary packaging. Please wash hands or use gloves when handling the cartridges.

The melt blown polypropylene sediment cartridge is the first on the inlet side, followed by the carbon block cartridge(due south) (CBC10-10). Both of these cartridges can exist installed with either end in offset. The membrane goes into the membrane housing with the o-band finish get-go. Be sure RO Membrane is pushed into Membrane housing equally far equally it will get.

-

vii. RO Unit of measurement Installation

The RO unit is unremarkably mounted to the correct or left sink cabinet sidewall, depending on where supply tank is to exist located. More often than not the unit of measurement is installed at the front of the cabinet and the tank at the rear.

To mount the unit of measurement, elevate it at least two" off the flooring, level it and mark the location of mounting holes needed. Drill hole for mounting screws and install screws allowing the mounting subclass slots to sideslip over them.

Note: If the chiffonier sidewalls are not solid, unit may sit on the floor with screws used just to keep it against the cabinet in a vertical position.

-

8. Pre-Make full and Supply Tank Placement

Pre-filling the storage tank is recommended so there is sufficient pressure to check for leaks and h2o to flush the carbon mail service filter. To do this connect the feed line that will serve the RO unit directly to the float tank. A 3/viii" x 1/4" reducer is provided for this purpose. Allow the water to fill the bladder until it stops. Close to tank valve, shut off the feed pressure level, release the tube from the reducer and remove the reducer from the tank valve.

The supply tank should exist placed under the counter or inside x feet of the RO unit of measurement.

Note: Tanks are pre-pressurized with air at 7 psi.

-

ix. Terminal Tubing Connections

With all components in place, complete final tubing connections with these guidelines:

- Tubing should follow contour of the cabinets.

- Cut tubing to correct length using square cuts and a proper cutting tool

- Make sure in that location are no crimps in the tubing.

- Go on tubing from the RO unit to the tank and faucet equally short as possible for good menstruation.

- The Bleed line is a brusque ane/4" tube continued to the membrane housing. On this tube is a iii" cylindrical drain flow restrictor. This is where the drain line connects to the RO unit of measurement. Exercise non remove the bleed menses restrictor equally this volition cause a failure in the organization.

Icemaker hookup

(optional and requires a T plumbing fixtures and additional close-off valve not supplied with RO unit)

The RO unit tin can be continued to whatsoever standard fridge icemaker or ice maker/h2o dispenser.

To complete this operation, connect a T with a shut off valve into the faucet tubing and route tubing to the refrigerator. (Hooking up to existing copper tubing is not recommended due to possible corrosion) Plow off icemaker inside freezer prior to turning off the existing tap water supply line to the refrigerator. Turn on the icemaker after the RO organization has been drained several times and the tank has a full supply of water.

Icemaker lines are ofttimes run in the rafters of unfinished basements or finished basements with drop ceilings and then upward to the fridge. If the basement has a difficult ceiling, this won't be an pick and the line would have to exist run through cabinets. In cases where a basement or cabinets connecting sink and refrigerator are not available, icemaker connections cannot be made.

Note: Before any service is performed on the RO system, turn off icemaker valve and icemaker unit of measurement. Turn back on only after RO system has been sanitized and flushed out.

System Beginning-Up

Prior to start-up

- Check all fitting connections.

- Open up ball valve, allow system to pressurize and check for leaks.

- Open valve on float tank and open faucet until water flows.

- Shut faucet, wait 5 minutes and check for leaks.

- Permit system to produce a full tank of RO water. (2-three hours)

Flushing System and Checking Operation

- Flip the faucet lever up and this will proceed faucet on. Practice this and allow tank to completely drain of all water.

- Close faucet and re-inspect system for leaks.

- Permit arrangement to produce water for 4 hours, at this indicate the bladder tank will exist total.

- Open up faucet again and allow tank to empty for a 2nd time.

- Close faucet and permit unit to produce some other tank of water.

- At this point supply line to ice maker connection (optional) may be opened and RO water is ready to be consumed.

Replacing Filters & Sanitizing the Organization

Each year the filters in the system should be replaced. Commonly the membrane can exist replaced every other yr, simply the pre-filters and postal service-filter should be changed annually and in some cases more often.

Filter Replacement

- Turn off valve on RO bladder tank.

- Turn off feed h2o pressure level.

- Open RO faucet to relief force per unit area.

- Using the supplied housing wrench remove the filter housing.

- Discard old filters.

- Clean filter housings with a cleaning castor.

- Follow sanitizing steps in "Sanitizing the System" section

- Install new filters in organization.

- Remove and replace GAC Mail filter. Remove fittings from erstwhile post filter, re-apply Teflon record and install fittings in new post filter.

- Turn on feed pressure.

- Open up tank valve.

- Allow h2o in tank to affluent out post filter and run to bleed until empty. Run 2 more than complete batches to drain before using water.

Membrane Replacement

- Remove the supply tube from the end of the membrane housing that has just 1 tube.

- Unthread the cap from the membrane housing.

- Remove membrane using a pair of pliers.

- Make clean membrane housing with a brush.

Annotation: When installing a new membrane be certain to button the membrane into the housing as far as it will get. Each fourth dimension the filters are replaced it is recommended that the arrangement be sanitized.

Sanitizing the Arrangement

After all filters are removed from the system, housings have been cleaned, tank is empty, and faucet is open...

- Add i gallon of h2o to a clean saucepan.

- Add 1 teaspoon of unscented household bleach.

- Add ane cup of this solution to each filter housing.

- Tighten filter housings with solution on RO assembly.

- Connect membrane housing and feed tube.

- Open up tank valve and feed pressure valve.

- Allow water to fill the RO housing assembly until water comes out of faucet.

- Close the faucet.

- Allow water to run for five minutes.

- Shut-off feed pressure.

- Allow solution to stand for thirty minutes.

- Open faucet and allow system to drain.

- Remove h2o from housings before installing new filters and membrane.

- Install new filters, tighten housings, and reconnect all tubing connections.

- Open feed pressure valve and check for leaks.

- Let the system to make a full tank of water.

- Run two cycles to drain to rinse out sanitizing solution before using water.

Troubleshooting

RO Systems are highly sensitive to pressure and temperature. RO Membranes always perform better under college pressures. They produce more water, faster, and of better quality with high pressure. The vast bulk of problems with RO Systems are a effect of depression pressure. The furnishings of low pressure include water constantly running to the bleed, irksome water production and depression water volume available in storage tank. In these cases where low pressure exists, a booster pump will be required.

On the following page is a table showing RO Membrane operation over a range of temperatures and pressures. Membranes are tested at 65 psi of pressure and temperature of 77 degrees. For each incremental change in either variable, membrane functioning changes accordingly. Higher pressures increase production and vice versa.

To troubleshoot a poor performing RO Organisation an accurate measure of the pressure and temperature of h2o will be required. This will crave a pressure level gauge to determine exactly what the water force per unit area is that is feeding the membrane. Descriptions of water force per unit area such as good, high or strong, unfortunately, are no help in diagnosing an RO System.

View This Chart SeparatelyPressure Temperature Chart | ||||||||||||||||

| Temp °F | 35 PSI | xl PSI | 45 PSI | 50 PSI | 55 PSI | 60 PSI | 65 PSI | 70 PSI | 75 PSI | 80 PSI | 85 PSI | ninety PSI | 95 PSI | 100 PSI | 105 PSI | 110 PSI |

| 45° | 0.2321 | 0.2653 | 0.2985 | 0.3316 | 0.3648 | 0.3979 | 0.4311 | 0.4643 | 0.4974 | 0.5306 | 0.5638 | 0.5969 | 0.6301 | 0.6632 | 0.6964 | 0.7296 |

| 46° | 0.2417 | 0.2762 | 0.3108 | 0.3453 | 0.3798 | 0.4144 | 0.4489 | 0.4834 | 0.5179 | 0.5525 | 0.5870 | 0.6215 | 0.6561 | 0.6906 | 0.7251 | 0.7597 |

| 47° | 0.2513 | 0.2872 | 0.3231 | 0.3590 | 0.3949 | 0.4308 | 0.4667 | 0.5026 | 0.5385 | 0.5744 | 0.6103 | 0.6462 | 0.6821 | 0.7179 | 0.7538 | 0.7897 |

| 48° | 0.2609 | 0.2981 | 0.3354 | 0.3726 | 0.4099 | 0.4472 | 0.4844 | 0.5217 | 0.5590 | 0.5962 | 0.6335 | 0.6708 | 0.7080 | 0.7453 | 0.7826 | 0.8198 |

| 49° | 0.2704 | 0.3091 | 0.3477 | 0.3863 | 0.4250 | 0.4636 | 0.5022 | 0.5409 | 0.5795 | 0.6181 | 0.6568 | 0.6954 | 0.7340 | 0.7726 | 0.8113 | 0.8499 |

| fifty° | 0.2800 | 0.3200 | 0.3600 | 0.4000 | 0.4400 | 0.4800 | 0.5200 | 0.5600 | 0.6000 | 0.6400 | 0.6800 | 0.7200 | 0.7600 | 0.8000 | 0.8400 | 0.8800 |

| 51° | 0.2896 | 0.3309 | 0.3723 | 0.4137 | 0.4550 | 0.4964 | 0.5378 | 0.5791 | 0.6205 | 0.6619 | 0.7032 | 0.7446 | 0.7860 | 0.8274 | 0.8687 | 0.9101 |

| 52° | 0.2991 | 0.3419 | 0.3846 | 0.4274 | 0.4701 | 0.5128 | 0.5556 | 0.5983 | 0.6410 | 0.6838 | 0.7265 | 0.7692 | 0.8120 | 0.8547 | 0.8974 | 0.9402 |

| 53° | 0.3087 | 0.3528 | 0.3969 | 0.4410 | 0.4851 | 0.5292 | 0.5733 | 0.6174 | 0.6615 | 0.7056 | 0.7497 | 0.7938 | 0.8379 | 0.8821 | 0.9262 | 0.9703 |

| 54° | 0.3183 | 0.3638 | 0.4092 | 0.4547 | 0.5002 | 0.5456 | 0.5911 | 0.6366 | 0.6821 | 0.7275 | 0.7730 | 0.8185 | 0.8639 | 0.9094 | 0.9549 | 1.0003 |

| 55° | 0.3279 | 0.3747 | 0.4215 | 0.4684 | 0.5152 | 0.5621 | 0.6089 | 0.6557 | 0.7026 | 0.7494 | 0.7962 | 0.8431 | 0.8899 | 0.9368 | 0.9836 | one.0304 |

| 56° | 0.3374 | 0.3856 | 0.4338 | 0.4821 | 0.5303 | 0.5785 | 0.6267 | 0.6749 | 0.7231 | 0.7713 | 0.8195 | 0.8677 | 0.9159 | 0.9641 | 1.0123 | 1.0605 |

| 57° | 0.3470 | 0.3966 | 0.4462 | 0.4957 | 0.5453 | 0.5949 | 0.6444 | 0.6940 | 0.7436 | 0.7932 | 0.8427 | 0.8923 | 0.9419 | 0.9915 | 1.0410 | i.0906 |

| 58° | 0.3566 | 0.4075 | 0.4585 | 0.5094 | 0.5603 | 0.6113 | 0.6622 | 0.7132 | 0.7641 | 0.8150 | 0.8660 | 0.9169 | 0.9679 | 1.0188 | ane.0697 | 1.1207 |

| 59° | 0.3662 | 0.4185 | 0.4708 | 0.5231 | 0.5754 | 0.6277 | 0.6800 | 0.7323 | 0.7846 | 0.8369 | 0.8892 | 0.9415 | 0.9938 | 1.0462 | ane.0985 | i.1508 |

| 60° | 0.3757 | 0.4294 | 0.4831 | 0.5368 | 0.5904 | 0.6441 | 0.6978 | 0.7515 | 0.8051 | 0.8588 | 0.9125 | 0.9662 | one.0198 | 1.0735 | ane.1272 | i.1809 |

| 61° | 0.3853 | 0.4403 | 0.4954 | 0.5504 | 0.6055 | 0.6605 | 0.7156 | 0.7706 | 0.8256 | 0.8807 | 0.9357 | 0.9908 | 1.0458 | 1.1009 | 1.1559 | 1.2109 |

| 62° | 0.3949 | 0.4513 | 0.5077 | 0.5641 | 0.6205 | 0.6769 | 0.7333 | 0.7897 | 0.8462 | 0.9026 | 0.9590 | 1.0154 | ane.0718 | 1.1282 | 1.1846 | 1.2410 |

| 63° | 0.4044 | 0.4622 | 0.5200 | 0.5778 | 0.6356 | 0.6933 | 0.7511 | 0.8089 | 0.8667 | 0.9244 | 0.9822 | 1.0400 | 1.0978 | 1.1556 | 1.2133 | 1.2711 |

| 64° | 0.4140 | 0.4732 | 0.5323 | 0.5915 | 0.6506 | 0.7097 | 0.7689 | 0.8280 | 0.8872 | 0.9463 | one.0055 | 1.0646 | i.1238 | 1.1829 | one.2421 | 1.3012 |

| 65° | 0.4236 | 0.4841 | 0.5446 | 0.6051 | 0.6656 | 0.7262 | 0.7867 | 0.8472 | 0.9077 | 0.9682 | one.0287 | one.0892 | 1.1497 | 1.2103 | 1.2708 | one.3313 |

| 66° | 0.4332 | 0.4950 | 0.5569 | 0.6188 | 0.6807 | 0.7426 | 0.8044 | 0.8663 | 0.9282 | 0.9901 | 1.0520 | 1.1138 | 1.1757 | ane.2376 | 1.2995 | 1.3614 |

| 67° | 0.4427 | 0.5060 | 0.5692 | 0.6325 | 0.6957 | 0.7590 | 0.8222 | 0.8855 | 0.9487 | 1.0120 | 1.0752 | 1.1385 | 1.2017 | 1.2650 | i.3282 | ane.3915 |

| 68° | 0.4523 | 0.5169 | 0.5815 | 0.6462 | 0.7108 | 0.7754 | 0.8400 | 0.9046 | 0.9692 | ane.0338 | one.0985 | 1.1631 | 1.2277 | 1.2923 | 1.3569 | ane.4215 |

| 69° | 0.4619 | 0.5279 | 0.5938 | 0.6598 | 0.7258 | 0.7918 | 0.8578 | 0.9238 | 0.9897 | 1.0557 | 1.1217 | 1.1877 | 1.2537 | 1.3197 | 1.3856 | 1.4516 |

| seventy° | 0.4715 | 0.5388 | 0.6062 | 0.6735 | 0.7409 | 0.8082 | 0.8756 | 0.9429 | 1.0103 | one.0776 | one.1450 | i.2123 | 1.2797 | 1.3470 | one.4144 | 1.4817 |

| 71° | 0.4810 | 0.5497 | 0.6185 | 0.6872 | 0.7559 | 0.8246 | 0.8933 | 0.9621 | ane.0308 | one.0995 | 1.1682 | 1.2369 | 1.3056 | ane.3744 | 1.4431 | 1.5118 |

| 72° | 0.4906 | 0.5607 | 0.6308 | 0.7009 | 0.7709 | 0.8410 | 0.9111 | 0.9812 | one.0513 | 1.1214 | 1.1915 | 1.2615 | one.3316 | one.4017 | ane.4718 | 1.5419 |

| 73° | 0.5002 | 0.5716 | 0.6431 | 0.7145 | 0.7860 | 0.8574 | 0.9289 | 1.0003 | 1.0718 | i.1432 | ane.2147 | i.2862 | ane.3576 | ane.4291 | ane.5005 | 1.5720 |

| 74° | 0.5097 | 0.5826 | 0.6554 | 0.7282 | 0.8010 | 0.8738 | 0.9467 | 1.0195 | 1.0923 | one.1651 | 1.2379 | one.3108 | 1.3836 | 1.4564 | 1.5292 | one.6021 |

| 75° | 0.5193 | 0.5935 | 0.6677 | 0.7419 | 0.8161 | 0.8903 | 0.9644 | i.0386 | 1.1128 | 1.1870 | 1.2612 | ane.3354 | ane.4096 | 1.4838 | one.5579 | 1.6321 |

| 76° | 0.5289 | 0.6044 | 0.6800 | 0.7556 | 0.8311 | 0.9067 | 0.9822 | 1.0578 | one.1333 | 1.2089 | i.2844 | 1.3600 | i.4356 | one.5111 | 1.5867 | 1.6622 |

| 77° | 0.5385 | 0.6154 | 0.6923 | 0.7692 | 0.8462 | 0.9231 | 1.0000 | i.0769 | 1.1538 | 1.2308 | i.3077 | 1.3846 | i.4615 | 1.5385 | 1.6154 | 1.6923 |

| 78° | 0.5480 | 0.6263 | 0.7046 | 0.7829 | 0.8612 | 0.9395 | one.0178 | 1.0961 | 1.1744 | 1.2526 | 1.3309 | 1.4092 | 1.4875 | 1.5658 | ane.6441 | 1.7224 |

| 79° | 0.5576 | 0.6373 | 0.7169 | 0.7966 | 0.8762 | 0.9559 | 1.0356 | ane.1152 | 1.1949 | 1.2745 | 1.3542 | 1.4338 | i.5135 | 1.5932 | 1.6728 | 1.7525 |

| 80° | 0.5672 | 0.6482 | 0.7292 | 0.8103 | 0.8913 | 0.9723 | 1.0533 | 1.1344 | 1.2154 | 1.2964 | 1.3774 | 1.4585 | 1.5395 | 1.6205 | 1.7015 | 1.7826 |

| 81° | 0.5768 | 0.6591 | 0.7415 | 0.8239 | 0.9063 | 0.9887 | one.0711 | one.1535 | 1.2359 | 1.3183 | 1.4007 | ane.4831 | i.5655 | 1.6479 | 1.7303 | 1.8126 |

| 82° | 0.5863 | 0.6701 | 0.7538 | 0.8376 | 0.9214 | one.0051 | ane.0889 | 1.1726 | 1.2564 | one.3402 | i.4239 | ane.5077 | one.5915 | 1.6752 | 1.7590 | i.8427 |

| 83° | 0.5959 | 0.6810 | 0.7662 | 0.8513 | 0.9364 | 1.0215 | i.1067 | 1.1918 | 1.2769 | 1.3621 | ane.4472 | one.5323 | 1.6174 | 1.7026 | i.7877 | ane.8728 |

| 84° | 0.6055 | 0.6920 | 0.7785 | 0.8650 | 0.9515 | 1.0379 | ane.1244 | i.2109 | ane.2974 | 1.3839 | 1.4704 | 1.5569 | 1.6434 | 1.7299 | 1.8164 | 1.9029 |

| 85° | 0.6150 | 0.7029 | 0.7908 | 0.8786 | 0.9665 | 1.0544 | 1.1422 | one.2301 | 1.3179 | 1.4058 | ane.4937 | 1.5815 | i.6694 | 1.7573 | 1.8451 | 1.9330 |

| 86° | 0.6246 | 0.7138 | 0.8031 | 0.8923 | 0.9815 | 1.0708 | 1.1600 | 1.2492 | ane.3385 | one.4277 | one.5169 | 1.6062 | one.6954 | ane.7846 | i.8738 | i.9631 |

| 87° | 0.6342 | 0.7248 | 0.8154 | 0.9060 | 0.9966 | 1.0872 | 1.1778 | one.2684 | 1.3590 | 1.4496 | 1.5402 | ane.6308 | 1.7214 | 1.8120 | ane.9026 | 1.9932 |

| 88° | 0.6438 | 0.7357 | 0.8277 | 0.9197 | ane.0116 | 1.1036 | 1.1956 | one.2875 | 1.3795 | 1.4715 | 1.5634 | ane.6554 | i.7474 | one.8393 | 1.9313 | two.0232 |

| 89° | 0.6533 | 0.7467 | 0.8400 | 0.9333 | i.0267 | ane.1200 | 1.2133 | 1.3067 | 1.4000 | 1.4933 | 1.5867 | i.6800 | 1.7733 | i.8667 | 1.9600 | 2.0533 |

| 90° | 0.6629 | 0.7576 | 0.8523 | 0.9470 | 1.0417 | 1.1364 | one.2311 | 1.3258 | one.4205 | ane.5152 | i.6099 | 1.7046 | ane.7993 | 1.8940 | 1.9887 | 2.0834 |

| 91° | 0.6725 | 0.7685 | 0.8646 | 0.9607 | 1.0568 | one.1528 | 1.2489 | i.3450 | 1.4410 | i.5371 | 1.6332 | 1.7292 | 1.8253 | ane.9214 | 2.0174 | 2.1135 |

| 92° | 0.6821 | 0.7795 | 0.8769 | 0.9744 | 1.0718 | ane.1692 | i.2667 | 1.3641 | 1.4615 | one.5590 | 1.6564 | i.7538 | ane.8513 | 1.9487 | two.0462 | 2.1436 |

| 93° | 0.6916 | 0.7904 | 0.8892 | 0.9880 | one.0868 | 1.1856 | 1.2844 | 1.3832 | ane.4821 | ane.5809 | 1.6797 | one.7785 | i.8773 | 1.9761 | 2.0749 | 2.1737 |

| 94° | 0.7012 | 0.8014 | 0.9015 | one.0017 | 1.1019 | ane.2021 | 1.3022 | 1.4024 | 1.5026 | 1.6027 | 1.7029 | one.8031 | 1.9032 | 2.0034 | 2.1036 | 2.2038 |

| 95° | 0.7108 | 0.8123 | 0.9138 | 1.0154 | 1.1169 | 1.2185 | 1.3200 | 1.4215 | 1.5231 | 1.6246 | i.7262 | 1.8277 | ane.9292 | 2.0308 | 2.1323 | two.2338 |

Exploded Reverse Osmosis Diagrams

Exploded Contrary Osmosis Diagram

Exploded Opposite Osmosis Diagram w/ Booster Pump

Exploded Opposite Osmosis Diagram w/ Delivery Pump

Exploded Reverse Osmosis Diagram w/ Permeate Pump

Other Resources

Reverse osmosis systems can remove contaminants that are unhealthy and possibly deadly through a combination of granular activated carbon, carbon cake & sediment filtration, and thin film membranes.

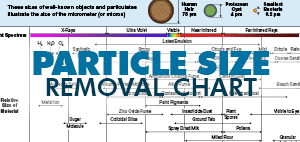

Nautical chart displaying the sizes of well-known objects and particulates, illustrated in the size of the micrometer (micron).

View the comparison chart for particle size removal of thin-picture membranes used in reverse osmosis systems.

Source: https://www.h2odistributors.com/pages/manuals/reverse-osmosis-installation.asp

Posted by: sandersonguitterotice.blogspot.com

0 Response to "How To Install Reverse Osmosis Membrane"

Post a Comment